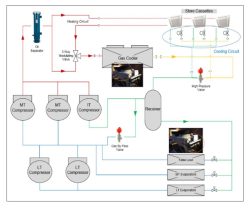

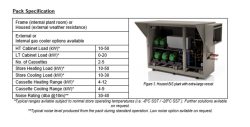

The ECO2 Booster integrated system (BIS) is a high-performing, efficient, compact, full CO2 refrigeration and space heating solution. Recovering the waste heat, which would normally be lost to the atmosphere, and directing it an area of the store or office. Reclaiming the wasted heat for space heating resulting in a more efficient and economical solution.

Key Themes: Heating Solution

Key Themes: Cooling Solution

Maintenance

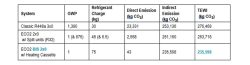

A TEWI comparison of a simple HT refrigeration plant, typical installed in small shops. Comparing a tradditional R448a scroll unit with a booster system and the BIS system (based on a 10-year life-cycle).

As part of a £1.8m investment, one of the UK's leading food processors engaged with Space to design, supply and install refrigeration equipment for a...

Read more

As part of a competitive tender process, Space Engineering successfully secured the multi phased upgrade works for an existing M&S retail site in Fosse Park....

Read more

Our valued customer needed to replace their high GWP refrigeration equipment for their picking freezer. As Space Engineering understand our clients needs, factoring both CAPEX...

Read moreWe’d love to hear from you. Please enter your details in the form below and we will get back to you.

We take your privacy seriously. We will keep your data safe and we won’t pass it on to any third parties.

Please see our privacy policy for more details.