Services: Turnkey Refrigeration Package

A luxury retailer selected us to deliver the refrigeration system and required electrical services for a high-end food court for employees located in the roof of a building in central London.

Achieving an environmentally sound solution without compromising safety or performance, while also creating a luxurious and attractive space, were the key drivers for this project. Armed with the customer’s clear vision, we delivered a complete refrigeration solution that would provide optimum performance without the harmful gasses associated with traditional refrigeration systems.

With the site located in central London, space was at a premium and it also presented some logistical challenges too, both of which we overcame through a customised solution.

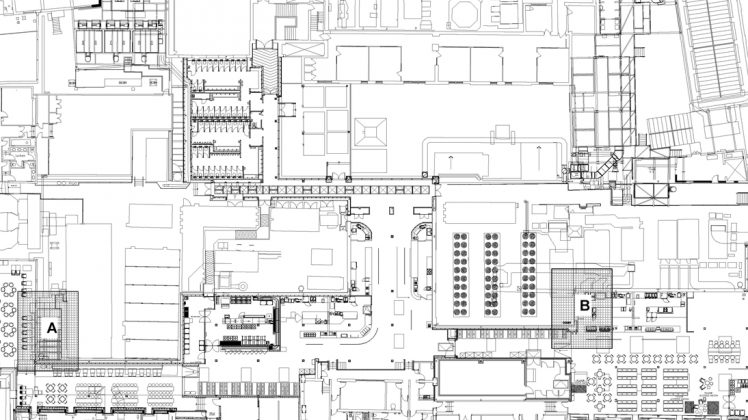

We created a full 3D design to identify the most cost, time and energy efficient refrigeration solution based on the customer’s requirements.

After thorough forward-planning, led by one of our experienced Project Managers, we installed and commissioned a customised and natural refrigeration system, cold rooms, and refrigerated cabinets and counters to efficiently and safely serve the variety of food outlets which would be located in the new food court.

The superior finish achieved for the food court, and the impressive reliability of the plant installed, are a testament to our proficiency and attention to detail in delivering solutions of outstanding quality to meet the very highest of standards expected by our customers.

We customised our tried and tested ECO₂ Mini Housed refrigeration unit, a powerful booster system offering superb performance, environmental credentials and a compact footprint. Designed for the convenience market, it operates on the single refrigerant CO₂ (R744). It has an extremely low a global warming potential of just one, providing an environmentally sustainable solution without compromising safety. Its in-built CO₂ leak alarm system was further enhanced with external pressure relief valves and an extract system for added security against refrigerant leaks and overheating.

The refrigerated cabinets and cold room suppliers were selected for their high quality, customisable products to meet our customer’s specific design and operating requirements. We managed the supply of 24 custom-built cabinets and serve-over counters, three cold rooms and a sophisticated Danfoss control system, safely delivering these to the roof of the building.

Our experienced teams carefully coordinated the installation and commissioning process to minimise site issues which could impact the schedule. Thanks to our collaborative approach and effective planning, all aspects of the refrigeration system and required electrical services were installed and commissioned on programme.

We were part of a carefully selected team of installers that worked collaboratively on this ambitious and unique project to deliver the following services:

Located on the roof of a building on a busy road in central London, access for the delivery of materials and equipment to the site was restricted. To overcome this challenge, we lifted and positioned the refrigerated cabinets, plant system and gas coolers onto the roof using a crane, working with all stakeholders, including the Highways Agency, to maintain the highest standards of safety throughout.

The detailed specification provided by the customer required us to work closely with a diverse supply chain which span multiple disciplines and geographical locations. Our collaborative approach and robust supply chain processes enabled us to deliver this project as an integrated solution to the complete satisfaction of the customer.

As part of a £1.8m investment, one of the UK's leading food processors engaged with Space to design, supply and install refrigeration equipment for a...

Read more

As part of a competitive tender process, Space Engineering successfully secured the multi phased upgrade works for an existing M&S retail site in Fosse Park....

Read more

Our valued customer needed to replace their high GWP refrigeration equipment for their picking freezer. As Space Engineering understand our clients needs, factoring both CAPEX...

Read moreWe’d love to hear from you. Please enter your details in the form below and we will get back to you.

We take your privacy seriously. We will keep your data safe and we won’t pass it on to any third parties.

Please see our privacy policy for more details.