02 Jun 2025

When it comes to building systems – whether it’s refrigeration, HVAC, or energy management – the smartest savings often happen long before installation begins.

A well-thought-out system design is more than a set of blueprints; it’s the foundation for lower running costs, higher efficiency, and long-term peace of mind. From early feasibility studies to smart control integration, here’s how proper planning can future-proof your investment.

Imagine trying to solve a puzzle without having all the pieces – or worse, not even knowing what the final picture is supposed to look like. That’s exactly what it’s like trying to design a building system without first carrying out a feasibility study.

A feasibility study isn’t just a box-ticking exercise – it’s the foundation of a well-designed, efficient, and future-proof system. It provides a comprehensive understanding of your site’s specific needs, existing limitations, and potential opportunities.

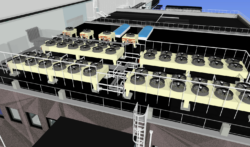

Through in-depth site assessments, technical analysis, and stakeholder input, a feasibility study helps uncover things you may not have considered – such as hidden structural challenges, changing energy demands, or regulatory hurdles. It also explores various solutions, compares their long-term benefits and costs, and identifies which one aligns best with your goals, budget, and operational requirements.

When done properly, this upfront planning leads to smarter decisions, reduced waste, and systems that perform better from day one. Whether you’re building a new facility or upgrading an existing one, the feasibility study is your roadmap to success – ensuring the project moves forward with clarity, confidence, and cost-efficiency.

When it comes to designing any building system – whether it’s refrigeration, HVAC, or energy management – load calculations are the unsung heroes that determine how well the system will perform over time.

Getting the load calculations right is absolutely critical. Overestimate your loads, and you end up with an oversized system that consumes more energy than necessary. Not only does this inflate your utility bills, but it also means your equipment may cycle on and off more frequently, which accelerates wear and tear. On the flip side, underestimating the load can be just as problematic – leading to systems that are constantly running at their limits, struggling to meet demand, and prone to early breakdowns or inefficiencies.

That’s why precise, data-driven load calculations are essential from the very start of a project. Engineers take into account a range of factors – from thermal loads and building orientation, to occupancy levels, equipment usage, lighting heat gains, and even local climate conditions. It’s not just about how the building functions today, but also how it may evolve in the future.

When done right, load calculations allow you to design a system that’s appropriately sized, energy-efficient, and cost-effective. The system works only as hard as it needs to – no more, no less – minimising unnecessary energy use and keeping maintenance requirements low.

Accurate load calculations ensure that the final design isn’t just technically sound, but operationally efficient, environmentally responsible, and aligned with your long-term business goals. It’s a small part of the process with a big impact on performance and savings.

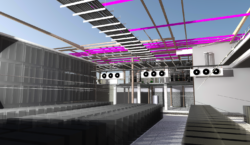

When people think of energy efficiency, airflow isn’t always the first thing that comes to mind – but it should be. Airflow management is one of the most overlooked yet essential elements of system performance, particularly in HVAC and refrigeration design.

Poor airflow management is a silent energy waster. If air isn’t flowing properly – whether due to poorly designed ductwork, blocked vents, or imbalanced systems – it can drastically reduce the efficiency of even the most advanced systems. This not only increases energy consumption but also impacts occupant comfort and equipment longevity.

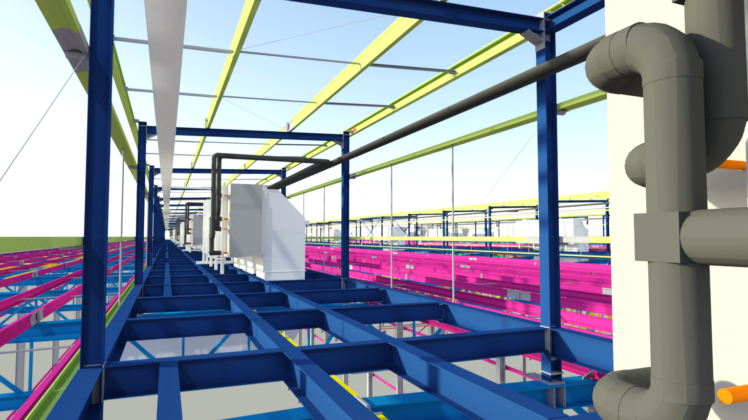

It starts with smart ductwork design. The shape, size, and routing of ducts affect how easily air travels through a system. Long, twisted, or undersized ducts force fans to work harder, using more energy. Next comes air balancing – a process that ensures consistent air distribution across different areas. Without proper balancing, some rooms might be too hot, others too cold, and the system constantly compensating to hit target conditions.

Good airflow management also plays a vital role in maintaining air quality, regulating humidity, and reducing system strain. It allows heating, cooling, and ventilation to work in sync, delivering targeted performance with minimal waste.

When airflow is managed well, you get maximum comfort with minimum effort – leading to lower bills, better air quality, and longer equipment life. It’s a win-win that starts with smart design.

In today’s world, designing for efficiency and sustainability isn’t just a trend – it’s a responsibility. And more than that, it’s a smart business move. From reducing running costs to meeting environmental targets, energy-efficient system design plays a key role in shaping the future of your building- and the planet.

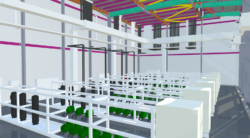

At the heart of this approach is intentional, data-led design. It starts with selecting the right components – high-efficiency compressors, low-emission refrigerants, and variable-speed drives – to minimise energy consumption without compromising performance. Then it’s about integrating those components into a system that operates holistically, rather than in silos.

Designing with sustainability in mind also means thinking long-term. Choosing materials that are durable and recyclable, designing for easy maintenance and upgrades, and ensuring the system can adapt to future demands or technologies. Whether it’s meeting BREEAM standards, reducing carbon emissions, or simply future-proofing your investment, sustainable design helps you stay ahead of regulations and rising energy costs.

From LED lighting and natural ventilation, to waste heat recovery and demand-based control systems, these design choices compound over time – delivering real savings and measurable environmental impact.

So instead of just building to meet today’s requirements, energy-efficient design asks: How can we do better – for performance, for people, and for the planet?

Because when sustainability is built into your systems from the start, it doesn’t just help the environment – it helps your bottom line too.

In a rapidly evolving industry, compliance is more than a checkbox – it’s a critical part of designing systems that are built to last. With increasingly strict regulations around refrigerants, energy consumption, carbon emissions, and environmental impact, system design today must look beyond current requirements and plan for what’s coming next.

Regulations around F-gases, decarbonisation targets, and building performance standards are changing fast. If your systems aren’t built with these in mind, you could face costly retrofits, downtime, or even non-compliance fines in the not-so-distant future. That’s why future-proofing your design from day one is key.

Smart, forward-thinking design means selecting low-GWP refrigerants, improving system efficiencies, and incorporating flexible technologies that can adapt to future upgrades or changes in legislation. It’s about staying ahead of the curve – not reacting to it.

But compliance doesn’t have to come at the cost of performance or innovation. In fact, the most efficient systems are often the most compliant. By aligning your design strategy with the latest best practices and regulatory guidance, you ensure that your system performs better, lasts longer, and avoids surprise costs down the line.

When compliance is built into the design – not bolted on after the fact – it becomes a seamless part of your efficiency, sustainability, and operational strategy.

At Space Engineering Services, we understand that effective system design is more than just meeting technical specifications – it’s about creating solutions that are efficient, sustainable, and future-ready. By integrating innovative approaches and prioritising sustainability, we aim to deliver designs that not only meet current needs but also anticipate future challenges. Our focus on energy efficiency and environmental responsibility ensures that our systems contribute to reducing operational costs and minimising carbon footprints. Through comprehensive services such as feasibility studies, load calculations, and compliance assessments, we ensure that every aspect of our design process is aligned with our clients’ goals and regulatory requirements.

We leverage cutting-edge technologies and independent expertise in refrigeration design to provide tailored solutions for the retail and service sectors. Our combined efforts focus on delivering systems that are not only innovative but also practical and sustainable. By embracing such a holistic approach, we help our clients achieve:

By prioritising intelligent design and sustainability, we are committed to delivering engineering solutions that provide lasting value and support a greener future.

Ready to explore smarter solutions for your site?

Get in touch with our engineering experts today or check out our case studies to see how design drives performance. Learn More: www.space-engineering.co.uk.

We’d love to hear from you. Please enter your details in the form below and we will get back to you.

We take your privacy seriously. We will keep your data safe and we won’t pass it on to any third parties.

Please see our privacy policy for more details.